This article's purpose is to help wood based panel processing and edgebanding companies., or simply put cut to size manufacturers, understand how to choose an online configurator for such services..

First of all, it is important to understand the key concepts, and all the acronyms used in the software industry.

Configure, Price, Quote or CPQ stands for Configure, Price, Quote. It refers to a software system used by panel processing companies to assist in the process of configuring products or services, determining their pricing, and generating quotes for customers. CPQ software is particularly valuable for businesses that offer complex products or services that can be customized to meet specific customer needs, in our case cut to size and edgebanding services.

In this article we will cover and focus on most of the details and examples from other websites that offer a specific CPQ for online boards cut to size and edgebanding, and CNC machining services you need to take in consideration if you're thinking about investing in such online system for panel cut to size, edgebanding, and CNC machining.

1. Understanding CPQ software for cut to size and edgebanding processes

1.1 Specifics for panel processing

CPQ software is particularly useful in the context of panel cut to size and edgebanding due to the complexity and customization involved in these processes. Here are the specifics of how CPQ software can be beneficial:

1.1.1 Configuration

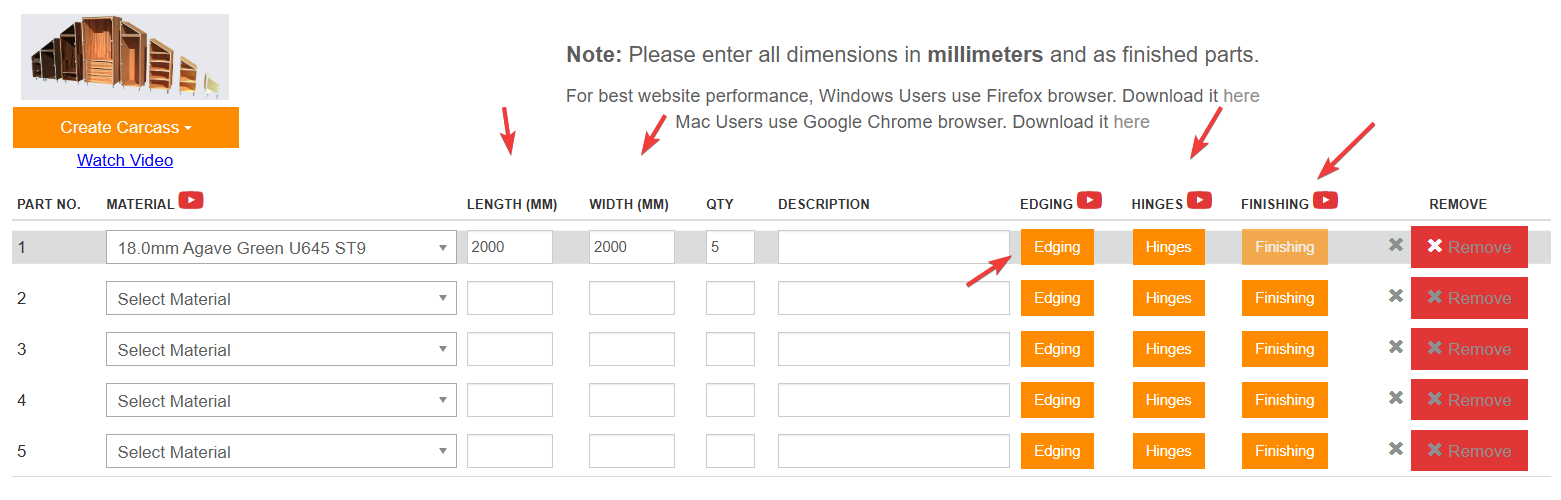

- Customization of Parts: Customers can specify the exact dimensions for their parts, fiber orientation, materials, and finishes for their panels.

- Edgebanding Options: Customers can choose from various edgebanding materials, colors, and thicknesses. The software can present these options and guide the customer through the selection process.

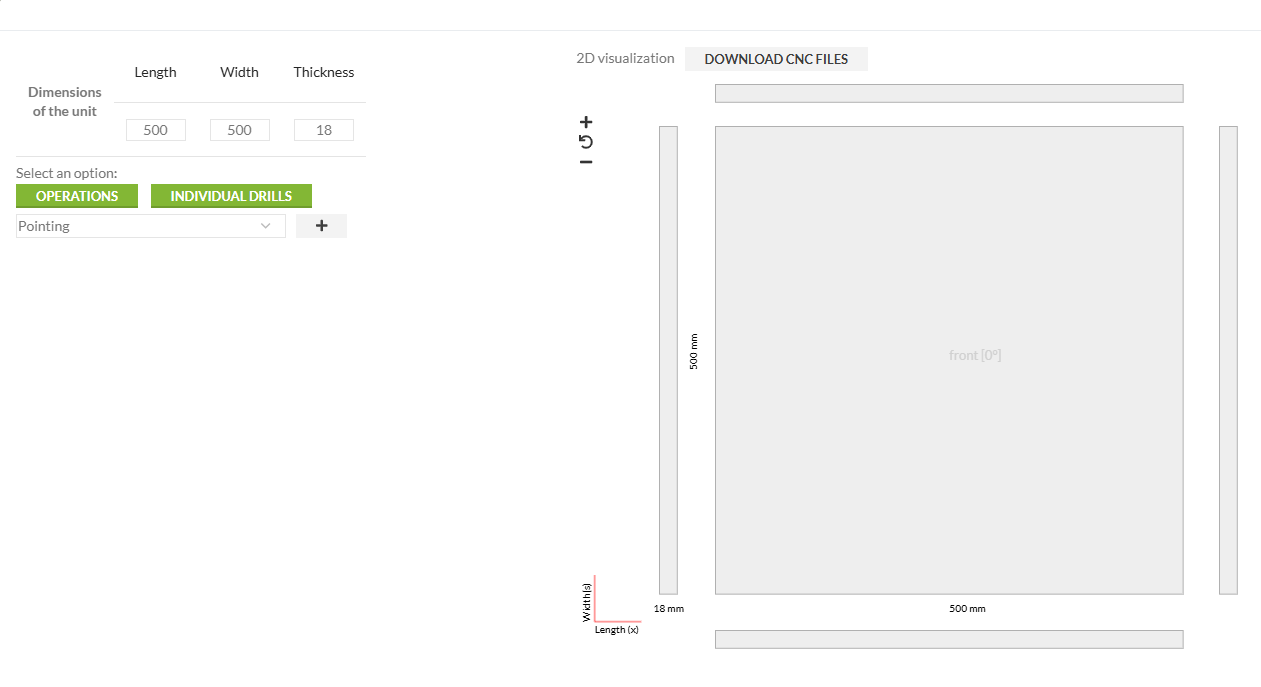

- Visual Configuration: Some CPQ solutions offer 3D visualization, enabling customers to see a virtual representation of their customized panel with selected edgebanding, helping them make informed decisions.

1.1.2 Pricing

- Accurate Pricing Calculations: CPQ software can calculate prices based on the exact dimensions of the panels, the type and amount of material used, and the selected edgebanding. It ensures that all factors, including labor, waste, and overhead, are considered.

- Discounts and Promotions: The software can apply tiered pricing lists, relevant discounts or promotional offers, providing customers with the best possible price while maintaining profitability.

- Dynamic Pricing Adjustments: As customers adjust their configurations, the CPQ software dynamically updates the pricing, offering real-time feedback on cost implications.

1.1.3 Quoting

- Professional Quote Generation: CPQ software generates detailed and professional quotes that include all the specifics of the customer's configuration. This can include detailed cutting patterns, descriptions, dimensions, material specifications, and pricing breakdowns.

- Quick Turnaround: Automating the quoting process significantly reduces the time required to produce a quote, allowing sales teams to respond to customer inquiries more rapidly.

- Error Reduction: By automating the calculation and configuration processes, CPQ software minimizes human errors, ensuring that quotes are accurate and reliable.

1.1.4 Additional Benefits

- Integration with ERP, CRM, PIM, or E-Commerce Systems: CPQ software can integrate with other systems, ensuring seamless data flow across the organization. This integration helps in maintaining up-to-date inventory levels, tracking customer interactions, and managing orders. Always check for platform specifics, like for example, check if there is a direct compatibility with your E-Commerce platform, eg. Shopify, Magento, Prestashop, Woocommerce, etc.

- Order Management: Once a quote is accepted, CPQ software can facilitate the creation of detailed work orders for the manufacturing team, ensuring that all specifications are accurately communicated and executed, including post-processor files for the production machinery.

- Scalability: CPQ software can handle a large volume of custom orders, making it easier for businesses to scale their operations without compromising on accuracy or customer satisfaction.

2. Key features to look for on a CPQ

2.1 Customization capabilities

Panel processing is a complicated industry with a lot of configurations for each workflow and process. Here are the some details that you need to take into consideration.

- Ability to handle various panel sizes and materials.

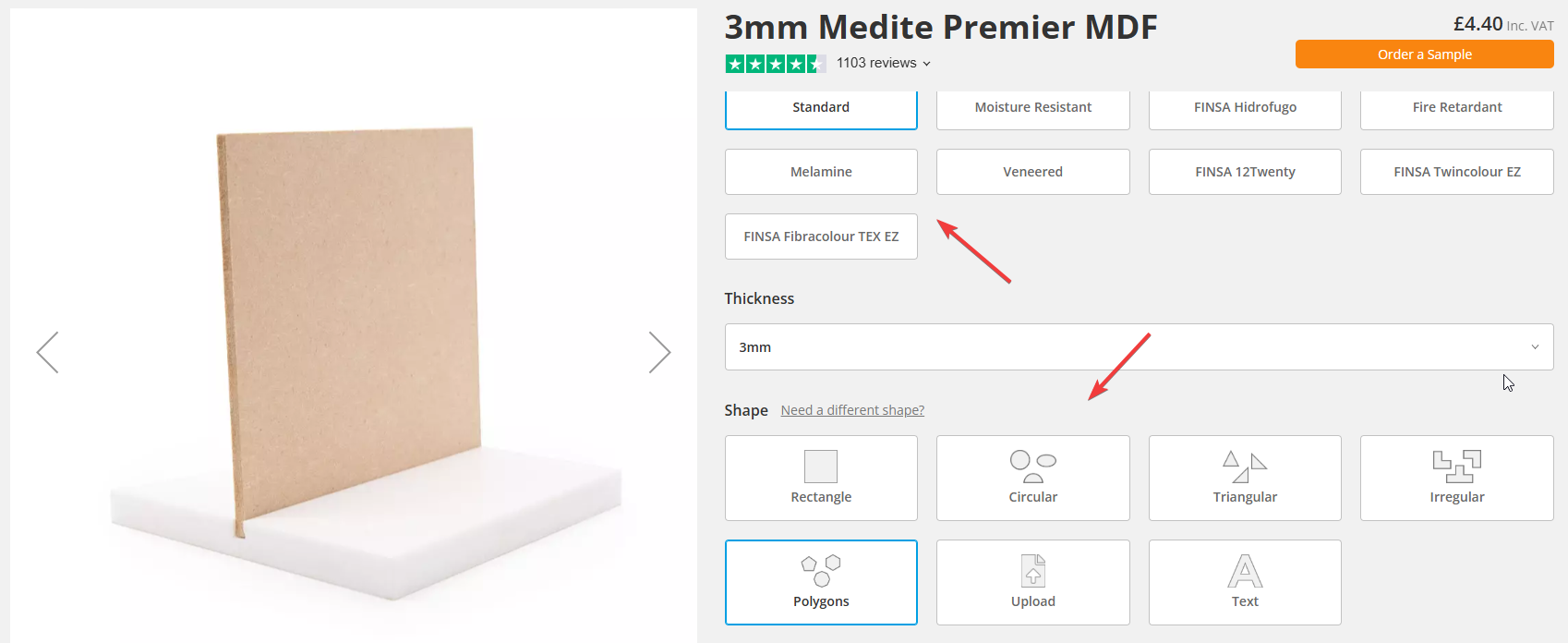

- Extensive Material Library: The CPQ software should have a comprehensive library of pre-loaded materials, including common sheet goods like plywood, MDF, melamine, hardwoods, plastics, and even solid surfaces.

- Custom Material Support: Look for software that allows you to add custom materials with specific attributes like thickness, density, and cost. This ensures flexibility for handling unique projects or niche materials.

- Parametric Size Configuration: The software should allow customers to define panel sizes with precise dimensions, including length, width, and thickness. Not to mention industry specifics, like grain orientation. Check if it handles imperial or metric units, depending on your target market.

- Minimum and Maximum Size Limits: The software should have configurable minimum and maximum size limitations to ensure it aligns with your production capabilities and avoids processing orders outside your workable range. For example, adding a default trim to all the boards you are using.

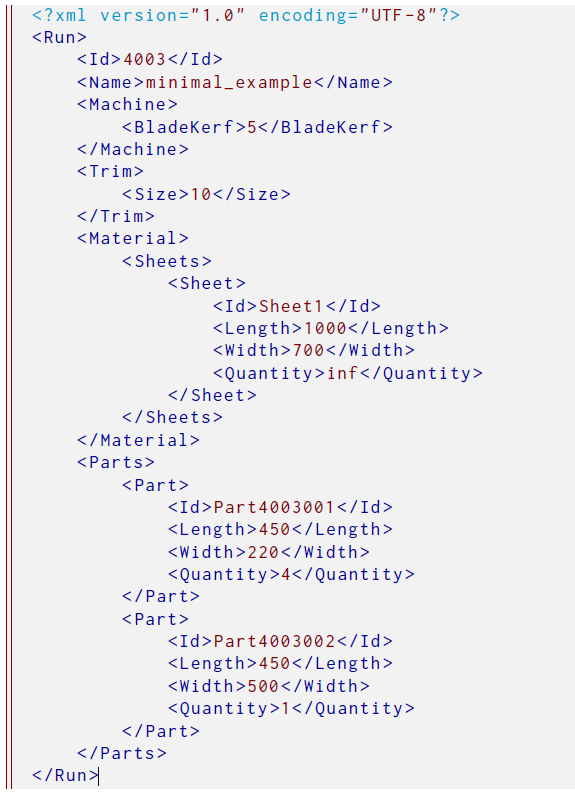

- Material Waste Minimization: Look for CPQ software that integrates with cutting optimization algorithms. This helps minimize material waste by efficiently nesting parts on panels during the cutting process, saving on costs and maximizing material utilization. What informations do you have about the cutting algorithm? Can you still use your cutting optimization software or can be integrated with?

Flexibility in configuring unique customer requirements.

- Hole Drilling and Machining: Does the software allow customers to specify locations and sizes for drilled holes, dowel placements, or other required machining operations? This is crucial for projects requiring pre-drilled components for assembly. Does is have direct integration with fittings and accesories manufacturers like say Hafele, Hettich or Blum.

- Edgebanding Customization: The software should offer a wide range of edgebanding options, including various materials, thicknesses, and pre-finished colors. Additionally, it should allow customers to define edgebanding application methods like full wrap, applied edges, or specific edge profiles.

- Multiple Edge Details: For complex projects, consider software that allows customers to define different edgebanding for various edges of a single panel. This caters to intricate designs requiring contrasting or unique edge treatments.

- Special Cutouts and Grooves: Look for CPQ software that allows customers to define shapes for cutouts or grooves within the panels. This is essential for tasks like installing hardware, creating signage, or incorporating decorative elements.

- Text and Image Uploads: Does the software allow customers to upload custom text or images for incorporation onto the panels or maybe to add some other extra details needed for manufacturing? This can be valuable for personalized projects with logos, engravings, or specific design elements.

2.2 Pricing accuracy

- Real-time pricing updates. Does the platform provide a management for the pricing lists? Can you add multiple pricing lists or how do you manage discounts? Can you link a specific account to a certain price list? Or does it integrate with your other software system where it can automatically syncronize the prices?

- Integration with material and services cost databases. Can be automatically integrated with your other software for product syncronization? Take into consideration that usually these types of product, like melamine, mdf, or other panels have specific configuration that needs to be updated. Be aware that product updating is an easy task so you won't need to updated it manually or individually on each software you're storing informations about them.

2.3 Quoting Efficiency

- Automated quote generation. Does it need any manual intervention? Or it just calculates on his own based on your backend criteria? For all the calculation like edgebandings it's easy-peasy, but what about the cutting optimization? Does the CPQ has his own cutting optimization alghorithm, or is it integrated with yours? Does your cutting optimization software license type has this feature for programatic access?

- Professional quote templates. Are you able to modify the quotation templates both visually in terms of branding and colors or can you have multiple ones? Can you add your logo? Or maybe can you add a banner once in a while for marketing purposes?

2.4 Integration with Other Systems

Ensure the CPQ software integrates seamlessly with your existing Enterprise Resource Planning (ERP), E-Commerce or Customer Relationship Management (CRM) systems.

This two-way integration allows for real-time data flow, such as transferring customer information, order details, and inventory levels between systems.

This eliminates manual data entry and ensures everyone involved has access to the most up-to-date information. For example, the CPQ system can pull real-time inventory data from the ERP to ensure accurate quotes and avoid overselling. Additionally, it can push confirmed orders back to the ERP to streamline production planning.

- Machinery and equipment compatibility.

Verify compatibility between the CPQ software and your Computerized Numerical Control (CNC) machinery and other equipment used in the production process, like beamsaw and edgebanding machine.

This ensures the software can generate output files or instructions that are compatible with your specific machines, streamlining data transfer to the production floor.

Look for software that offers direct integration with common CNC machine controllers or supports industry-standard output formats like DXF or G-code or different post-processor formats like PTX, CPOUT, XML, or other formats. This eliminates the need for manual file conversion or manipulation, reducing the risk of errors and delays.

Typically, the vast majority of cut to size business are using table saws, beam saw, vertical saws and CNC from manufacturers like:

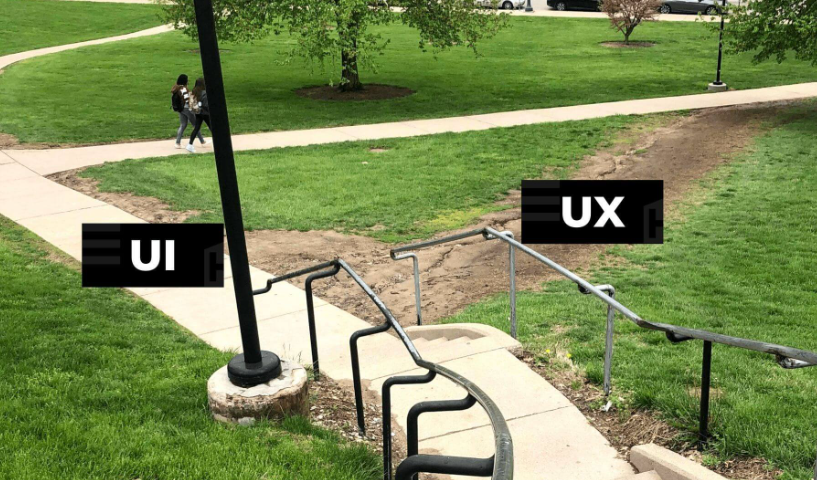

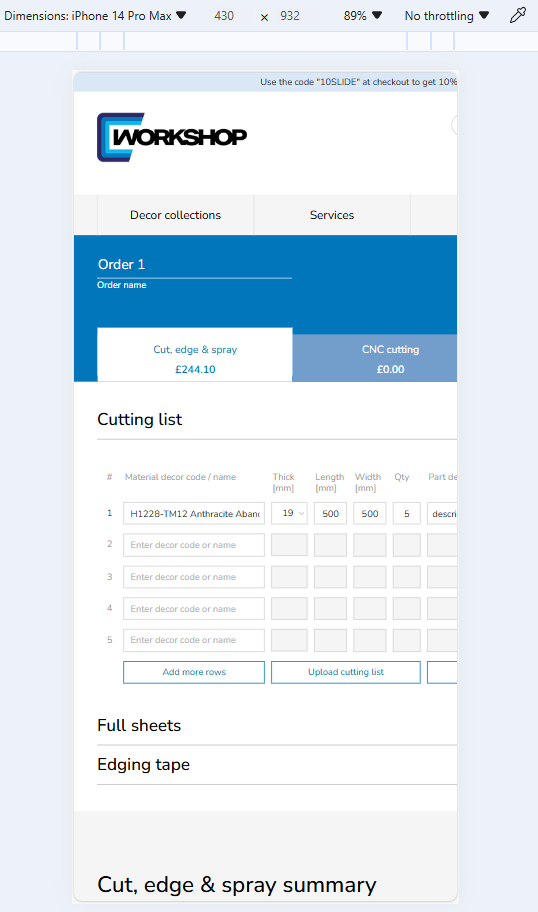

2.5 User-Friendly Interface and User Experience (UI & UX)

The CPQ software should have a clean and user-friendly interface that is easy to navigate for both customers and internal users, regardless of their technical expertise.

- A well-organized layout with clear menus, icons, and search functions minimizes the need for extensive training and allows users to quickly grasp the functionalities.

Role-Based Dashboards: Consider a CPQ system that offers customizable dashboards for different user roles.

- For example, sales representatives might have a dashboard focused on product configuration, quoting, and order generation, while production personnel might have a view centered on work order details, cutting patterns, and machine compatibility.

- This personalization ensures each user has a tailored experience that prioritizes the features most relevant to their tasks.

Visual Configurators:

- Integrate a visual configurator that allows customers to see a real-time preview of their customized panels with selected materials, edgebanding, and any special features.

- This interactive element enhances the customer experience and helps them make informed decisions by visualizing the final product before placing an order.

Responsive Design: Ensure the CPQ software offers a responsive design that adapts seamlessly to different devices, including desktops, tablets, and smartphones.

- This caters to customers who might want to configure and request quotes while on the go, improving accessibility and convenience.

Clear Error Handling: The software should provide clear and actionable error messages when users encounter issues during configuration or quoting.

- User-friendly error messages help users identify and rectify mistakes independently, reducing the need for IT support and streamlining the quoting process.

- Ease of use for different user levels. We all know that the clients within this industry like to have simple and speedy flow.

2.6 Scalability

- Ability to Grow with Your Business:

- As your business expands, the CPQ software you choose should be able to accommodate this growth. Look for a solution that scales to meet your increasing order volume, product offerings, and user base.

- Consider a cloud-based CPQ solution that can easily scale its resources to handle growing demands without requiring significant infrastructure upgrades on your end.

- Adaptability to Increasing Complexity and Volume:

- The CPQ software should be able to handle increasingly complex projects with intricate configurations.

- This includes features like multi-level product structures, nested components, and conditional rules that can adapt to various customer requirements.

- Ensure the software can efficiently manage a high volume of orders without compromising on processing speed or accuracy. Look for solutions that leverage robust data management capabilities and efficient algorithms to handle complex calculations quickly.

- Future-Proof Technology:

- Invest in CPQ software that is built with a future-proof architecture. This means the software is designed to adapt to evolving technologies and industry standards.

- Look for a vendor with a proven track record of ongoing development and innovation, ensuring your CPQ solution remains relevant and effective as your business and the industry landscape change.

By choosing a scalable CPQ software, you can ensure your investment supports your long-term growth objectives and adapts to the ever-changing demands of the panel processing industry.

3. Evaluating vendors

Choosing the right CPQ software vendor is crucial for a successful implementation. Here are some key factors to consider when evaluating potential vendors:

3.1 Reputation and experience

- Vendor's track record in the industry. Look for vendors with a strong track record in the wood panel processing and edgebanding industry. Their experience ensures they understand the specific needs and challenges of your business and can provide solutions tailored to your workflow.

- Research the vendor's experience with companies of similar size and complexity to yours.

- Customer testimonials and case studies. Investigate the vendor's existing customer base. Look for case studies and testimonials from companies in the panel processing industry who have successfully implemented their CPQ software. This provides valuable insights into the vendor's capabilities and the real-world benefits their solutions deliver.

3.2 Customer Support

- Availability of training and onboarding. Assess the quality of training and onboarding programs offered by the vendor. This includes training for both your sales representatives and internal operations team to ensure everyone feels comfortable using the CPQ software effectively. Look for vendors who provide comprehensive training materials, including video tutorials, user guides, and ongoing support resources.

- Ongoing technical support. Evaluate the vendor's approach to ongoing technical support. Ensure they offer multiple support channels, such as phone support, email ticketing systems, or live chat options, to address any issues that may arise after implementation. Consider the response times and the availability of technical expertise to resolve complex issues promptly.

3.3 Updates and Maintenance

- Frequency and ease of software updates. Investigate the vendor's update frequency for their CPQ software. Regular updates ensure you benefit from the latest features, bug fixes, and security patches. Look for vendors committed to continuous improvement and innovation, keeping your software solution at the forefront of technology.

- Policy on bug fixes and improvements. Evaluate the vendor's process for addressing bug fixes and implementing improvements based on customer feedback. A transparent and responsive approach ensures your concerns are addressed promptly, keeping your CPQ software functioning optimally.

3.4 Trial and Demo Options

- Availability of free trials or demos. Inquire about the availability of free trials or demo versions of the CPQ software. This allows your team to test the software firsthand and evaluate its functionality within your specific workflow.

- What to look for during a trial period. During the trial, focus on aspects crucial for your business. Assess the user interface, test configuration options with your most common panel materials and edgebanding choices. Evaluate the quoting process, including accuracy and speed. Explore integration capabilities with your existing systems.

4. Cost considerations

4.1 Initial investment

- Software purchase or subscription costs. CPQ software can be offered through various pricing models, including perpetual licenses, subscription fees, or tiered pricing based on features and user volume. Evaluate the upfront costs associated with different pricing models and choose the one that aligns best with your budget and long-term needs.

- Hardware and infrastructure requirements. While some CPQ software solutions might be cloud-based, others might require additional hardware or infrastructure upgrades on your end. Factor in any potential hardware costs, such as additional servers or workstations, and ongoing maintenance associated with this infrastructure.

4.2 Ongoing costs

- Maintenance fees. These fees are typically annual charges levied by the vendor to ensure your CPQ software remains functional and up-to-date.

Maintenance fees often cover a variety of services, including:

Software Updates: Regular updates provide access to new features, bug fixes, security patches, and compatibility improvements for your CPQ software.

Technical Support: Maintenance fees often entitle you to ongoing technical support from the vendor. This support can be delivered through various channels such as phone, email, live chat, or an online ticketing system.

Software Upgrades: In some cases, maintenance fees might include access to minor software upgrades. However, significant feature upgrades might require additional investment.

Carefully evaluate the scope of services included in the maintenance fees offered by different vendors.

Look for vendors who provide transparent breakdowns of what's covered under maintenance to ensure you're getting the value you expect.

- Costs for updates and additional features.

While maintenance fees might cover some updates, some vendors might have separate pricing structures for feature upgrades or major software revisions.

Consider how the vendor delivers new features and functionalities.

- Do they offer all updates as part of the maintenance fees, or are there additional costs for specific features?

- Are there different pricing tiers for access to advanced functionalities?

Understanding this structure is crucial for budgeting purposes.

You can avoid unpleasant surprises by having a clear picture of the costs associated with keeping your CPQ software solution at the forefront of technology with access to the latest features.

Here are some additional points to consider regarding ongoing costs:

- User Training Costs: While some vendors might include basic user training as part of their package, others might charge extra for comprehensive training programs. Factor in any potential training costs associated with onboarding your team on the new CPQ software.

- Data Migration Costs: If you're migrating data from existing systems to your new CPQ software, there might be associated costs for data conversion or integration services.

- Customization Costs: Some vendors might offer customization options to tailor the CPQ software to your specific needs. These customizations can come with additional development or implementation fees.

4.3 Return on Investment (ROI)

While the initial cost of CPQ software might seem like an expense, the benefits it delivers translate to significant cost savings and increased efficiency over time. Here's a closer look at the key areas where CPQ software can contribute to a positive ROI for your panel processing business:

4.3.1 Time Savings

- Streamlined Configuration and Quoting: CPQ software automates product configuration, pricing calculations, and quote generation.

This eliminates the need for manual calculations and data entry, saving your sales team and production personnel valuable time.

- Quantify the time your team currently spends on manual tasks related to configuring panels, edgebanding options, and generating quotes.

- With CPQ software, expect a significant reduction in this time, allowing your team to focus on more strategic activities like customer consultations, order fulfillment, and building customer relationships.

- Improved Sales Efficiency: By automating routine tasks and providing real-time quotes, CPQ software empowers your sales team to respond to customer inquiries faster and close deals more efficiently.

- Faster turnaround times for quotes can lead to increased sales conversion rates and improved customer satisfaction.

- Reduced Administrative Burden: Automating workflows and eliminating manual data entry minimizes administrative tasks associated with order processing. This frees up your team's time and resources to focus on higher-value activities.

4.3.2 Reduction in Errors and Waste

- Accurate Calculations and Pricing: Manual calculations are prone to errors, which can lead to mistakes in quotes, production orders, and material waste.

CPQ software automates calculations and pricing rules, ensuring accuracy throughout the workflow. This reduces the risk of errors in quotes and orders, minimizing the need for rework and improving customer satisfaction.

- Optimized Material Usage: Some CPQ software integrates with cutting optimization algorithms.

These algorithms efficiently nest parts on panels during the cutting process, minimizing material waste and maximizing material utilization. This can lead to significant cost savings on material purchases over time.

- Reduced Order Processing Errors: Manual order processing can lead to errors in order specifications or material requirements. CPQ software ensures accurate data transfer between departments, minimizing errors during production and reducing the need for order corrections or cancellations.

Quantifying the ROI

It's important to quantify the potential ROI of CPQ software before making an investment. Here are some metrics to consider:

- Time saved by sales and production teams

- Increase in sales conversion rates

- Reduction in errors and rework costs

- Savings from material waste reduction

- Improved customer satisfaction

By calculating the potential impact of CPQ software on these metrics, you can build a compelling business case for implementing this technology and demonstrate the long-term financial benefits it offers for your panel processing business.

5. Case Studies and Success Stories

Reading real-world examples of how other companies in the panel processing industry have successfully implemented CPQ software can be invaluable. These case studies showcase the tangible benefits and can help you envision how CPQ software can transform your own business.

5.1 Real-world Examples

Look for case studies from companies similar to yours in size, product offerings, and target market. This allows you to see how CPQ software can address challenges specific to your industry segment.

- Pay close attention to the specific functionalities of the CPQ software used in the case studies.

- Consider how these functionalities align with your own needs and requirements.

5.2 Benefits They Experienced

- Case studies typically highlight the quantifiable benefits companies achieved after implementing CPQ software.

- Look for metrics such as:

- Increased sales volume or conversion rates

- Reduced quote turnaround times

- Improved efficiency in order processing

- Minimized material waste

- Enhanced customer satisfaction

- Look for metrics such as:

- Understanding the specific benefits experienced by other companies can help you set realistic expectations for the impact CPQ software can have on your business.

5.3 Lessons Learned from Their Implementation Process

- Case studies often share valuable insights into the implementation process of CPQ software.

- Look for details on:

- Challenges encountered during implementation

- Strategies for successful user adoption and training

- Tips for maximizing the return on investment from CPQ software

- Look for details on:

By learning from the experiences of others, you can avoid potential pitfalls and ensure a smooth implementation of CPQ software within your own organization.

Here are some additional tips for finding case studies and success stories:

- Look on the websites of CPQ software vendors. They often showcase successful customer implementations.

- Search for industry publications or articles that discuss the benefits of CPQ software in panel processing.

- Attend industry trade shows or conferences where CPQ software vendors might be exhibiting and presenting case studies.

By incorporating real-world examples into your blog post, you can provide valuable and relatable content for your readers who are considering implementing CPQ software in their own panel processing businesses.

5.1 Real-world Examples

Look for case studies from companies similar to yours in size, product offerings, and target market. This allows you to see how CPQ software can address challenges specific to your industry segment.

- Pay close attention to the specific functionalities of the CPQ software used in the case studies.

- Consider how these functionalities align with your own needs and requirements.

5.2 Benefits They Experienced

- Case studies typically highlight the quantifiable benefits companies achieved after implementing CPQ software.

- Look for metrics such as:

- Increased sales volume or conversion rates

- Reduced quote turnaround times

- Improved efficiency in order processing

- Minimized material waste

- Enhanced customer satisfaction

- Look for metrics such as:

- Understanding the specific benefits experienced by other companies can help you set realistic expectations for the impact CPQ software can have on your business.

5.3 Lessons Learned from Their Implementation Process

- Case studies often share valuable insights into the implementation process of CPQ software.

- Look for details on:

- Challenges encountered during implementation

- Strategies for successful user adoption and training

- Tips for maximizing the return on investment from CPQ software

- Look for details on:

By learning from the experiences of others, you can avoid potential pitfalls and ensure a smooth implementation of CPQ software within your own organization.

Here are some additional tips for finding case studies and success stories:

- Look on the websites of CPQ software vendors. They often showcase successful customer implementations.

- Search for industry publications or articles that discuss the benefits of CPQ software in panel processing.

- Attend industry trade shows or conferences where CPQ software vendors might be exhibiting and presenting case studies.

6. Common Pitfalls to Avoid

Implementing CPQ software can be a transformative step for your panel processing business. However, there are some potential pitfalls to be aware of to ensure a successful implementation and maximize the return on your investment.

6.1 Overlooking Integration Needs

- CPQ software should seamlessly integrate with your existing business systems, such as ERP (Enterprise Resource Planning) and CRM (Customer Relationship Management) software.

- This ensures a smooth flow of data between systems and avoids the need for manual data entry, which can lead to errors and inefficiencies.

- Consider integration with other relevant systems, such as machinery and equipment control software used in your production process.

- This ensures data compatibility and streamlines communication between CPQ software and your manufacturing equipment.

6.2 Ignoring User Training

- Successful user adoption is crucial for maximizing the benefits of CPQ software.

- Ensure you provide comprehensive training for both your sales team and internal operations personnel who will be using the software on a regular basis.

- Training should cover all functionalities of the software, from product configuration and quoting to order generation and data management.

- Consider offering ongoing training resources, such as user guides, video tutorials, or knowledge base articles.

- This empowers users to find answers to their questions independently and troubleshoot minor issues.

6.3 Neglecting Future Needs

- Choose a CPQ software solution that is scalable and can grow with your business.

- Consider factors like increasing order volume, expanding product offerings, and potential growth in your user base.

- Cloud-based CPQ solutions often offer greater scalability compared to on-premise solutions.

- Invest in a CPQ software solution built with a future-proof architecture.

- This means the software is designed to adapt to evolving technologies and industry standards.

- Look for a vendor with a proven track record of ongoing development and innovation to ensure your CPQ software remains relevant and effective in the long run.

7. Making the Final Decision

Choosing the right CPQ software is a crucial step towards optimizing your panel processing business. Here are some key steps to guide you through the final decision-making process:

7.1 Checklist for Decision-Making

- Summarize the key points you've considered throughout your evaluation process.

- This might include:

- Functionality and features offered by different CPQ software solutions.

- Integration capabilities with your existing systems.

- User-friendliness and ease of use.

- Scalability and ability to grow with your business.

- Vendor reputation, experience, and customer support.

- Cost considerations, including initial investment and ongoing costs.

- Return on investment (ROI) potential.

- This might include:

- By revisiting your checklist and comparing different CPQ software options, you can identify the solution that best aligns with your specific needs and priorities.

7.2 Consulting with Stakeholders

- Involve relevant stakeholders from different departments within your company throughout the evaluation process.

- This might include representatives from sales, operations, production, and IT.

- Getting input from various stakeholders ensures that the chosen CPQ software will address the needs of different teams and workflows within your organization.

- Hold collaborative discussions with stakeholders to discuss the pros and cons of different CPQ software options and reach a consensus on the best choice for your business.

7.3 Final Evaluation Steps

- Once you've narrowed down your options to a few top contenders, consider taking advantage of free trial periods or demo versions offered by some vendors.

- This allows your team to test-drive the software firsthand and experience its functionalities within the context of your specific workflows.

- Schedule demos with shortlisted vendors to ask any remaining questions and get a clearer picture of their implementation process, training offerings, and ongoing support services.

8. Conclusion

In conclusion, implementing CPQ software can be a game-changer for your panel processing business. By automating workflows, streamlining processes, and minimizing errors, CPQ software empowers you to:

- Enhance customer experience with faster quote turnaround times and a wider range of configuration options.

- Increase efficiency by automating product configuration, quoting, and order processing.

- Reduce costs through minimized material waste, improved order accuracy, and streamlined workflows.

- Boost sales with faster quote generation and improved sales team productivity.

By carefully considering the factors outlined in this guide, you can make an informed decision when choosing CPQ software and unlock the potential for significant growth and profitability in your cut to size processing business.

This structure provides a comprehensive guide to help your readers make an informed decision when choosing CPQ software for panel cut to size and edgebanding, while also subtly promoting your own solutions and expertise.

In conclusion, implementing CPQ software can be a powerful driver of growth and efficiency for panel processing businesses. By carefully considering the factors outlined in this guide, you can choose the right solution to empower your team, streamline workflows, and unlock new levels of customer satisfaction.